Digital Console Redesign

2021

THE PRODUCT

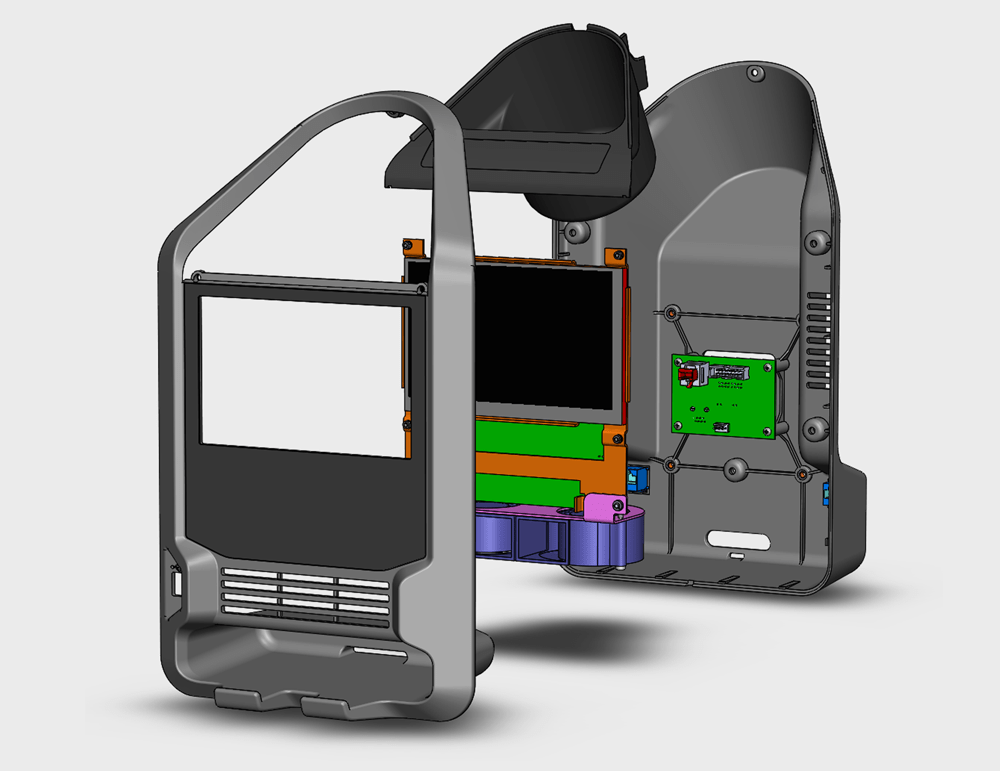

The existing steel tooling for the SCIFIT console housings was reaching the end of it’s life, resulting in cosmetic defects and reject parts. Recognizing the need for new tooling to sustain production, the team at Life Fitness saw this as an opportunity to reimagine the console, and they trusted DiMonte Group with the redesign effort.

MY CONTRIBUTIONS

Acting as the project lead, I brainstormed opportunities, sketched updated concepts, and 3D modeled production-ready geometry. The result was a redesigned console that improved on the legacy design by adding user-centric features, reducing part costs and reducing the overall footprint.

KEY OBJECTIVES:

- Identify areas for improvement – By analyzing the needs of modern and future users, I incorporated new features to enhance user experience and convenience.

- Enhance ergonomics – I slimmed down the console for better hand clearance, improving the overall usability.

- Refresh the styling – I updated the design to align with the SCIFIT product line, giving the console a modern, cohesive look.

- Add features and to improve convenience – I added phone and tablet resting areas, providing added convenience for the modern user.

- Simplify manufacturing – I eliminated the need for expensive and unreliable side-actions in the injection mold tooling, designing with ease of manufacturing in mind.

DESIGN PROCESS

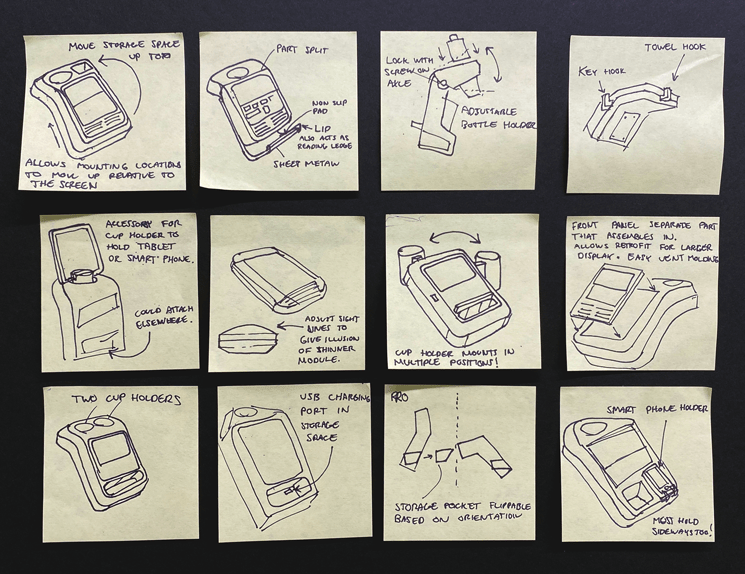

Creative brainstorming

I started with creative brainstorming, creating quick “post-it note” sketches to capture and organize the initial concepts.

Planning

Then, I mapped out the handlebar positions for the seven different machines this console would be attached to in SolidWorks. This helped me understand where the console footprint could expand or or shrink.

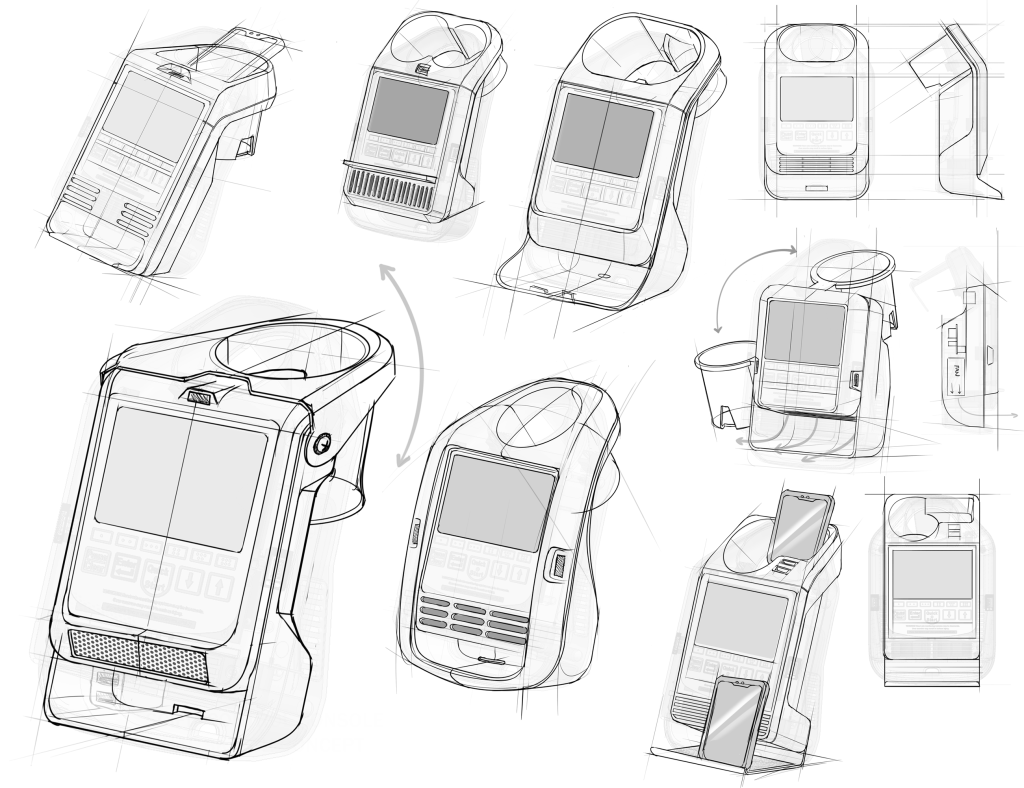

Sketching

Using the Solidworks data as an underlay I sketched multiple styling concepts, thoughtfully integrating the client’s favorite ideas from the post-it note phase. After several client feedback sessions, I had a final concept that fulfilled Life Fitness’s functional and aesthetic objectives.

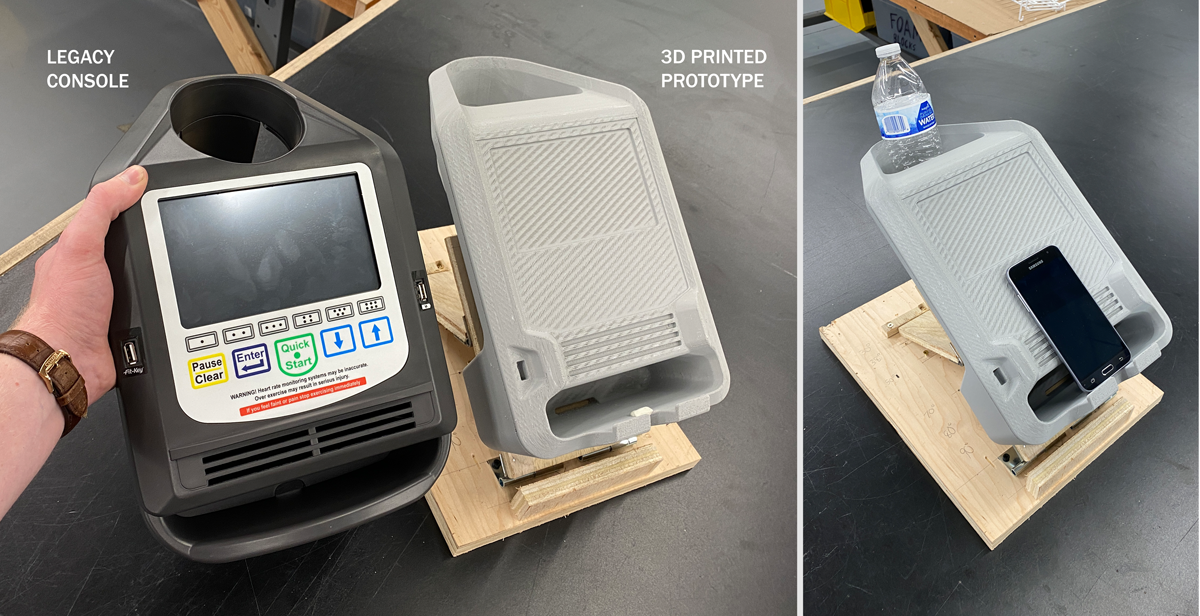

I used a 3D printed prototype to evaluate the new phone and water bottle holder features. An adjustable stand allowed us to test the new geometry through a range of mounting angles.

3D Modeling:

The legacy design used a massive and complex side action to form the cupholder area. My redesign separated the cupholder into a third part, simplifying the overall design, reducing tooling costs, and extending the life of the new tooling. I also refined the interior mounting brackets for easier assembly and manufacturing. In the end, I delivered a production-ready CAD package that Life Fitness seamlessly brought into production.

FINAL PRODUCT