Game Controller Redesign

2020

INTRO

During the pandemic lockdown, I revisited my old Nintendo 64 and the games I grew up playing. While the experience was nostalgic, I found the iconic trident-shaped controller less comfortable than I remembered. Leveraging the resources at the DiMonte Group, I set out to redesign and create a custom controller tailored to my hands, improving both ergonomics and functionality. This project also served as a hands-on opportunity to refine my skills in sculpting with Castilene clay and modeling complex, curvature-continuous geometry in SolidWorks.

OVERVIEW

- Reverse engineering

- Clay modeling

- Solidworks modeling

- Print and decorate

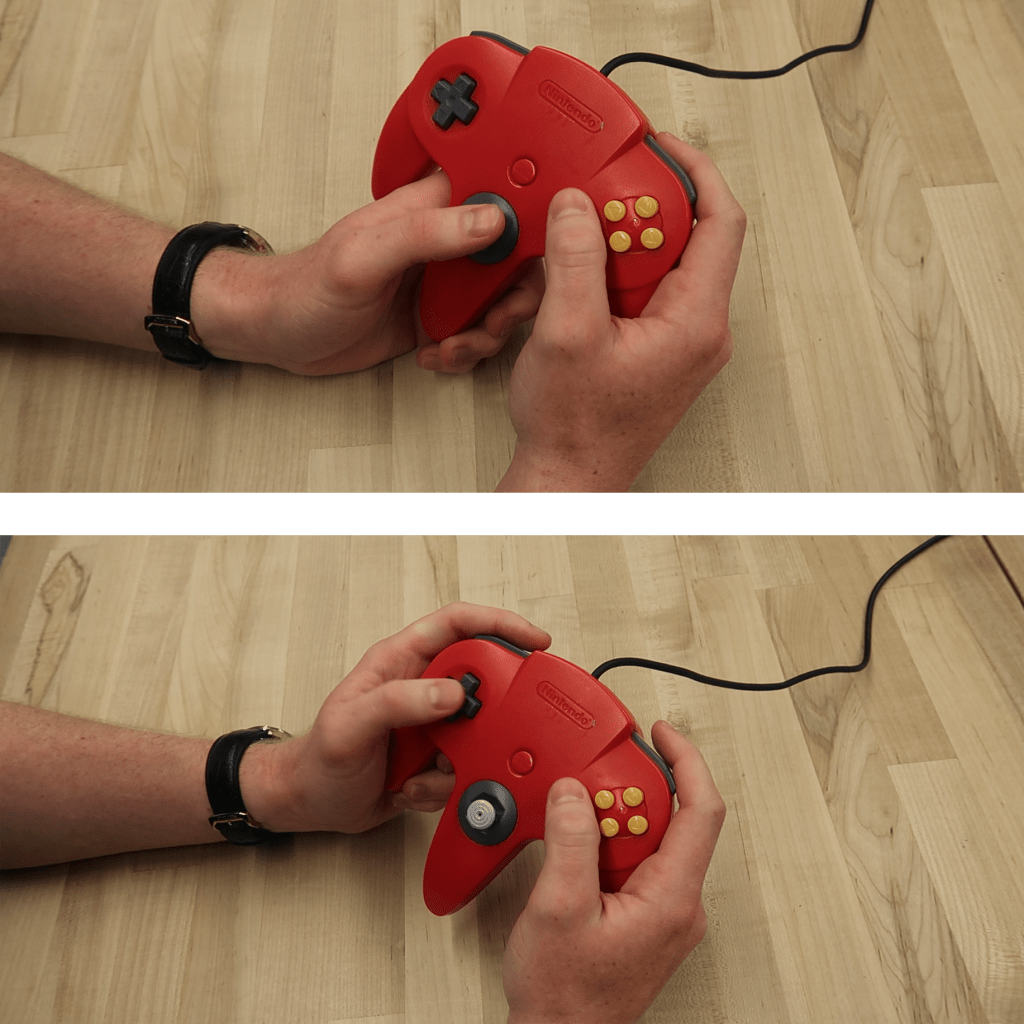

Original N64 Controller Issues

- 3 handled design makes it difficult to switch between using the directional pad and joystick

- Left shoulder button is inaccessible when using the joystick

- Handles are too small for my hand size

- Center “start” button is can be hard to find without looking at the controller

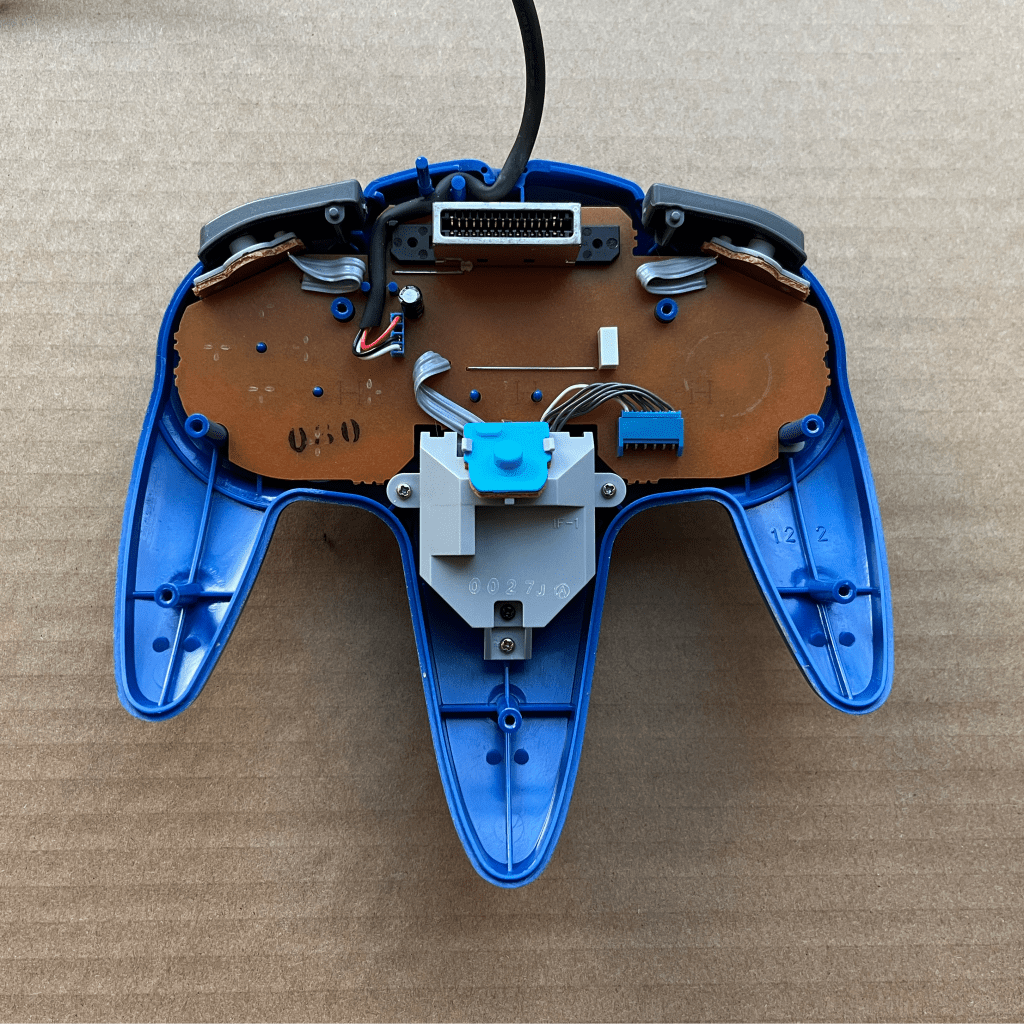

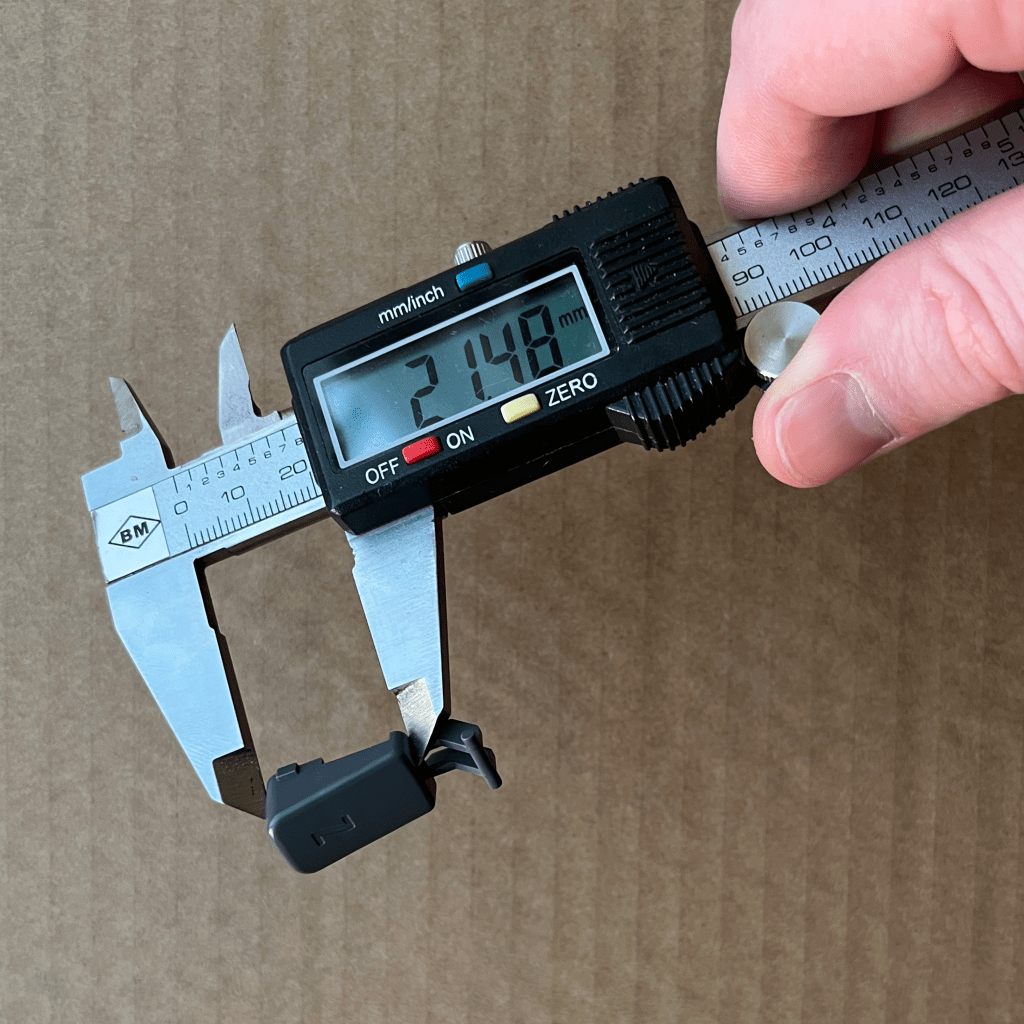

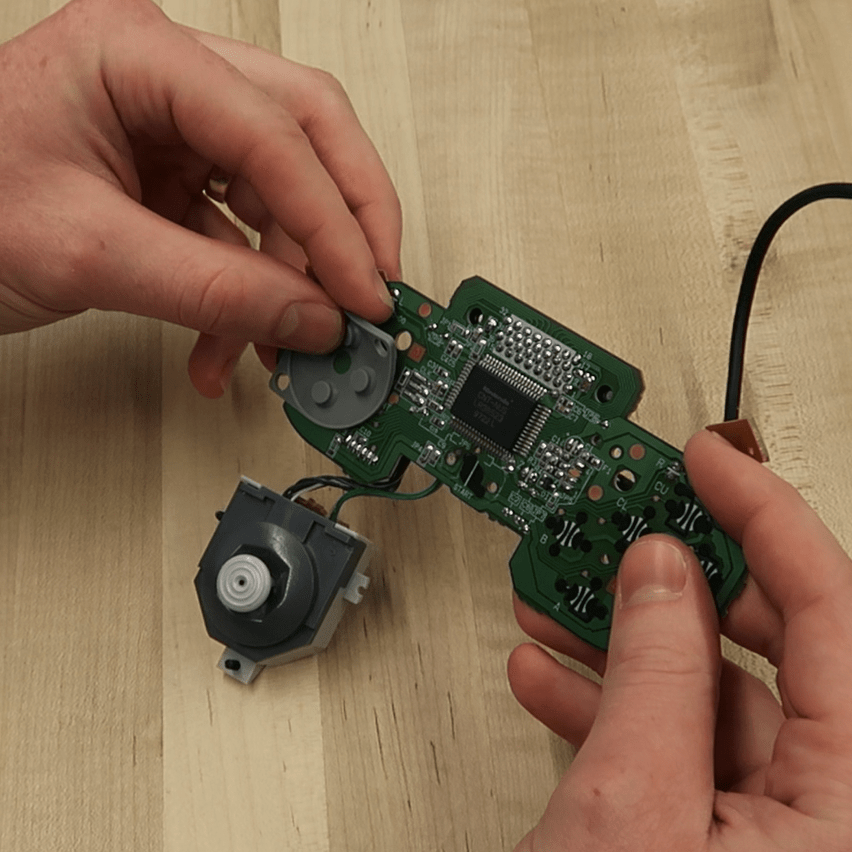

Reverse Engineering

I began by disassembling the original Nintendo 64 controller to understand its internal components and functionality. I determined that I would be able to reuse the existing buttons and reposition the joystick to the left side for my two-grip configuration. Using calipers and SolidWorks, I 3D modeled each component and mated them into an assembly to ensure proper fit and part alignment.

Clay Modeling

3D Scanning

I used the DiMonte Group’s laser scanner to generate a highly detailed 3D mesh of the clay model, which served as a precise reference for 3D modeling the controller design.

The 3D scanner produced a raw mesh file with extra faces from the scanning environment, requiring cleanup and alignment. Once refined, I integrated the mesh into my SolidWorks assembly to begin modeling the controller housings.

SolidWorks Modeling

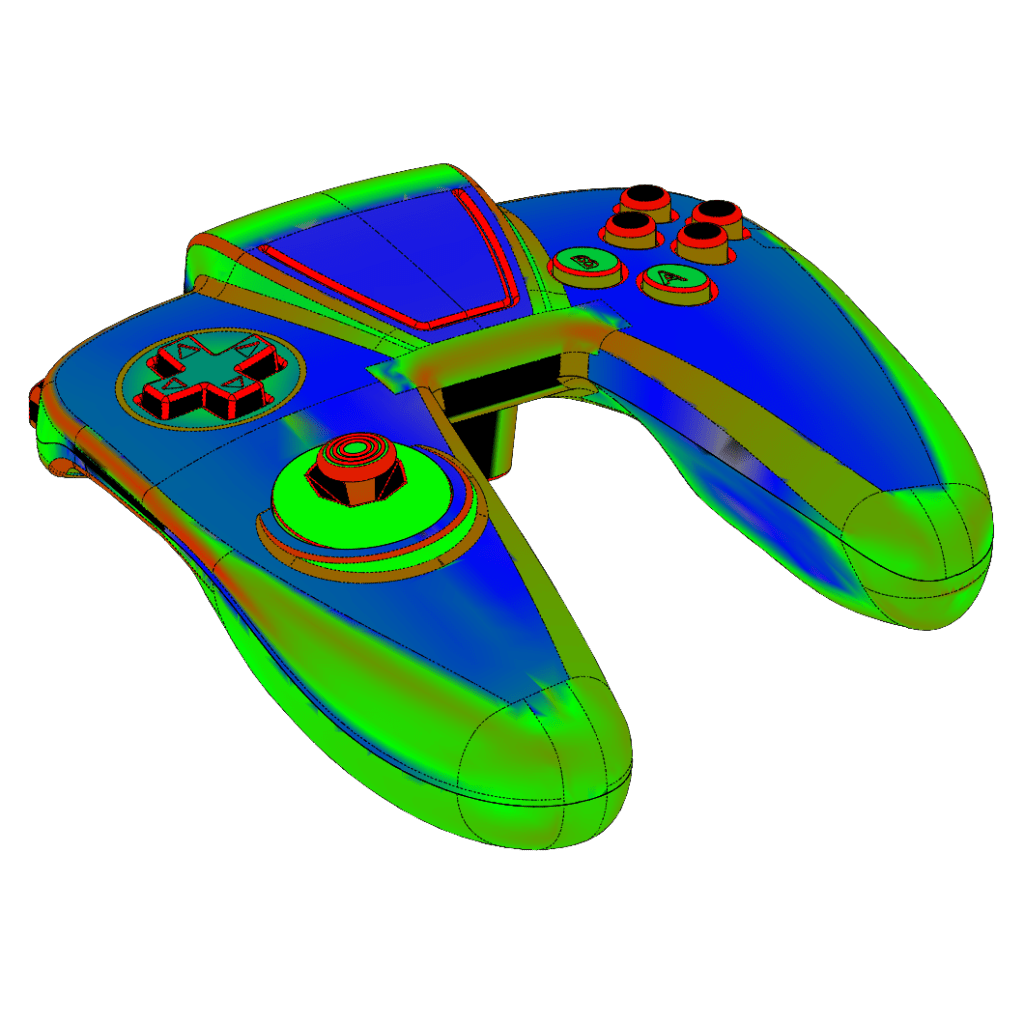

Comparison between scan and final model

Curvature analysis of final model

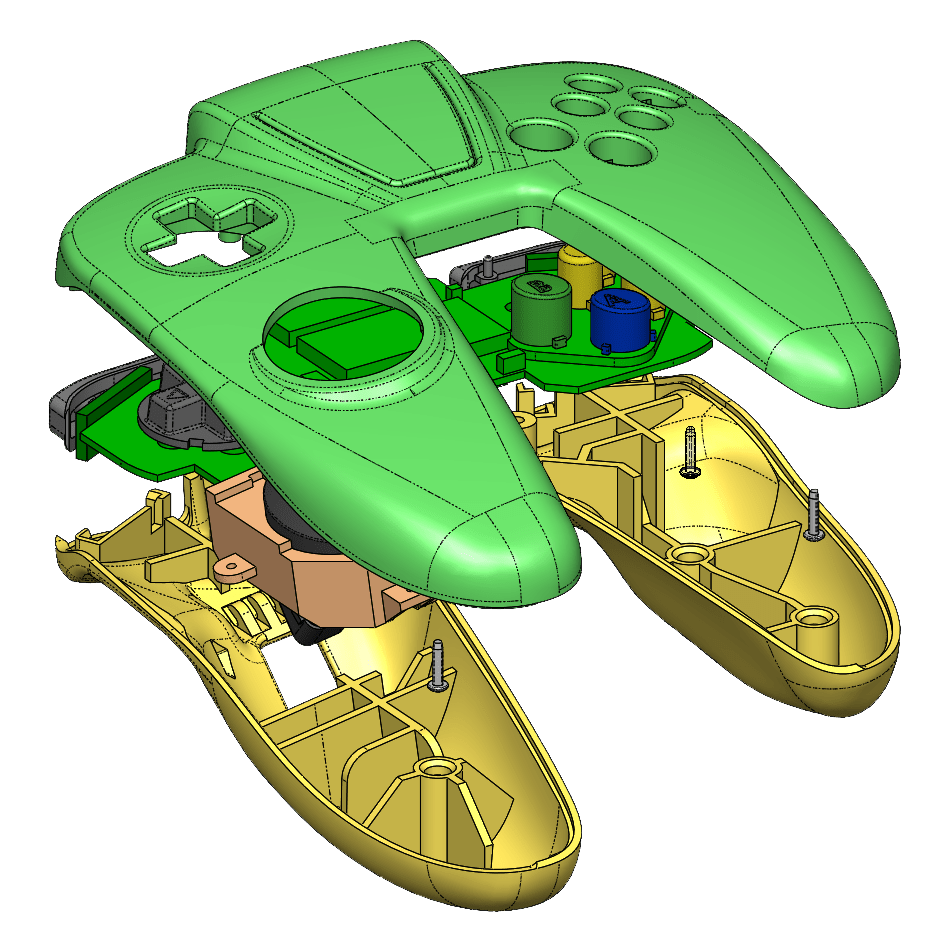

Exploded view of final model

Final Functional Controller

Final Assembly Steps

- Print the final geometry on DiMonte Group’s in house FDM 3D printers

- Test assembly fitment to make sure all the buttons were working

- Meticulously filled and sanded all outside cosmetic surfaces

- Prime surfaces and spray paint